Laser Tube Cutting Machine

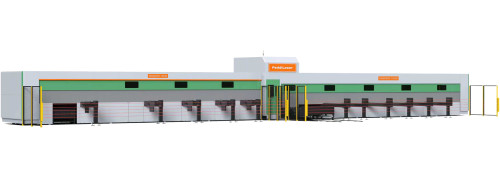

PeddiWPC 12036

Capable of efficiently cutting large-diameter, heavy-duty, and extremely long tubes

Overview

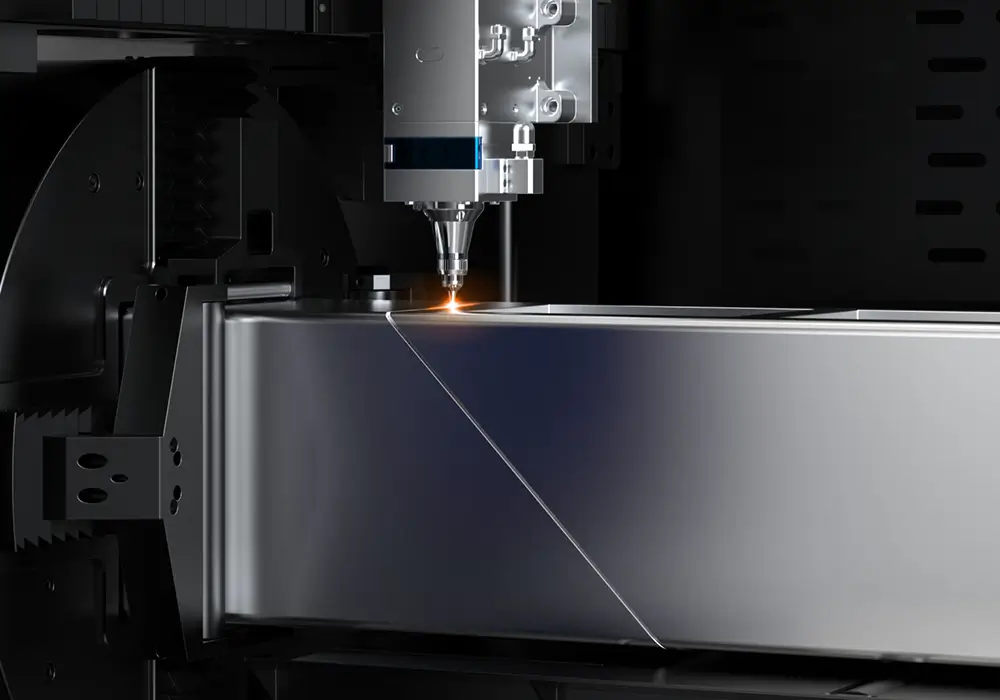

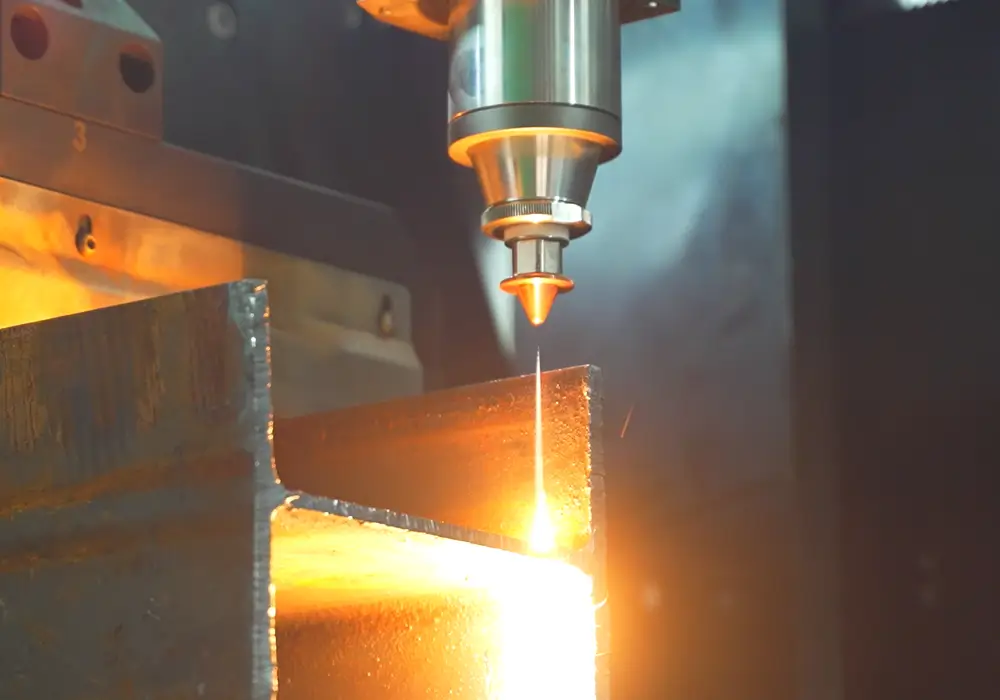

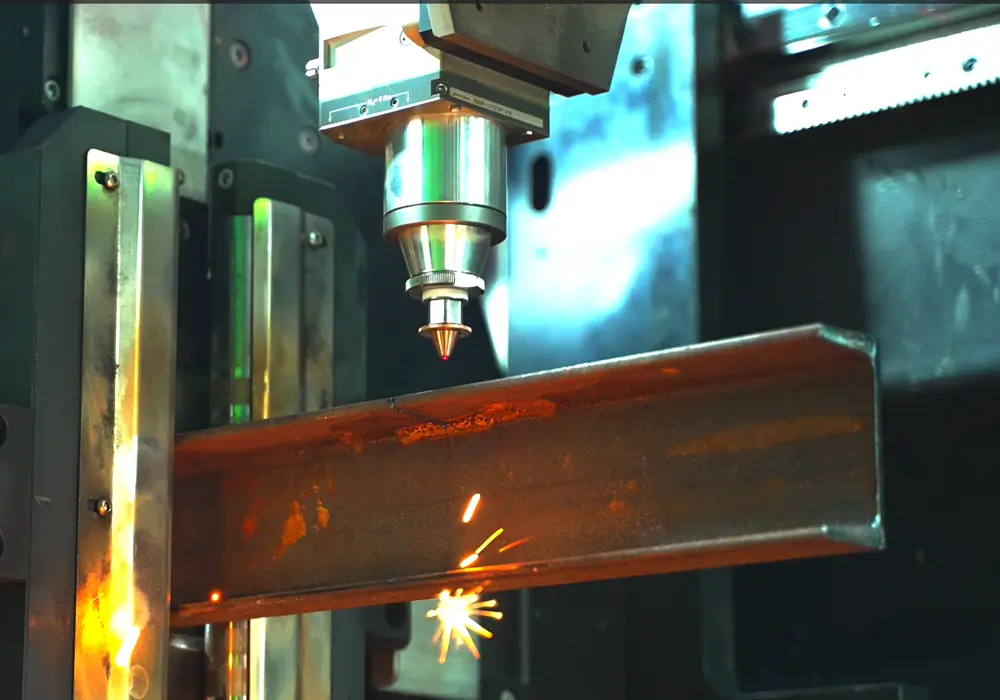

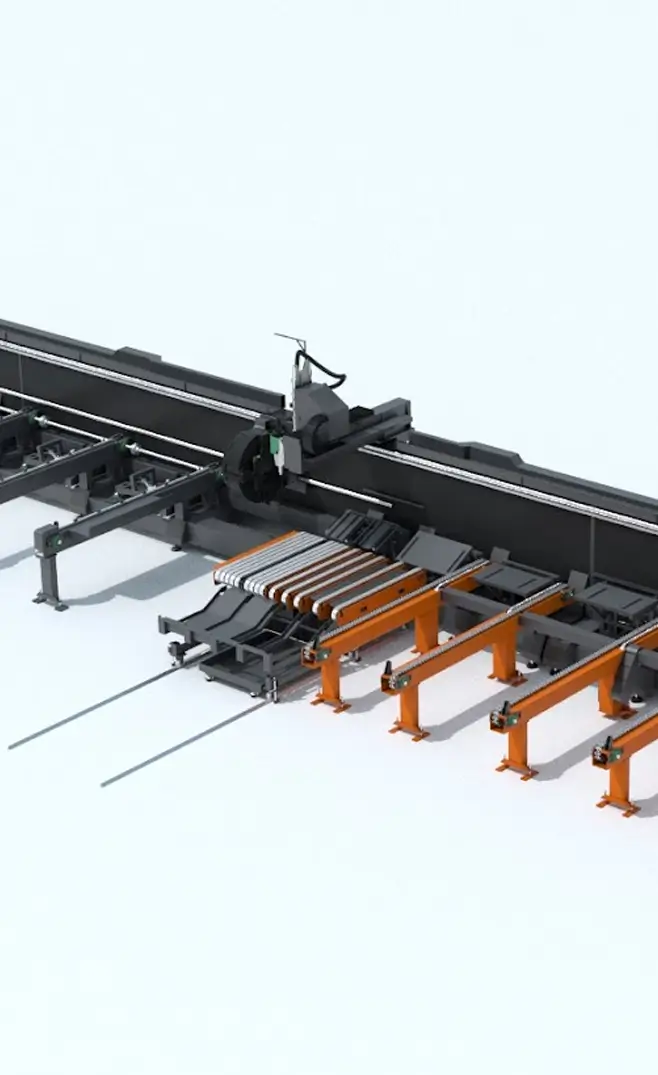

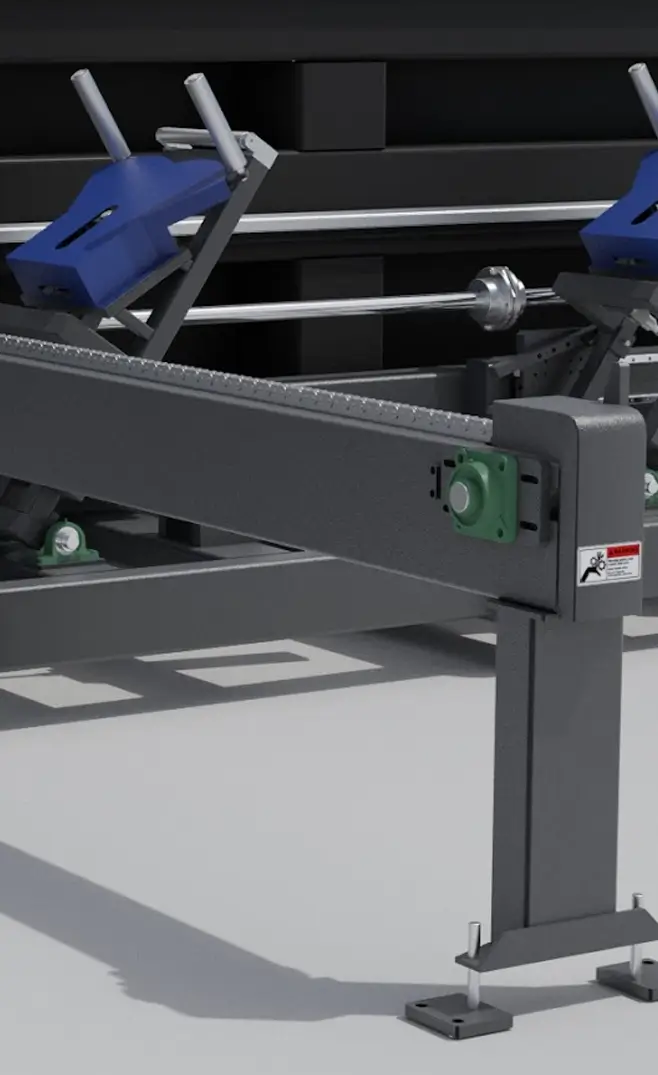

The PeddiWPC 12036 laser tube cutting machine turns heavy tube fabrication into a single-step profit center. Engineered for large-diameter and extra-long stock, the machine’s side-mounted chuck and reinforced bed keep every length locked solid so you get clean, repeatable cuts without secondary grinding or re-clamping. The result is faster throughput, tighter tolerances, and more billable hours on the floor—all in one rugged package built for structural, oil-field, and architectural work.

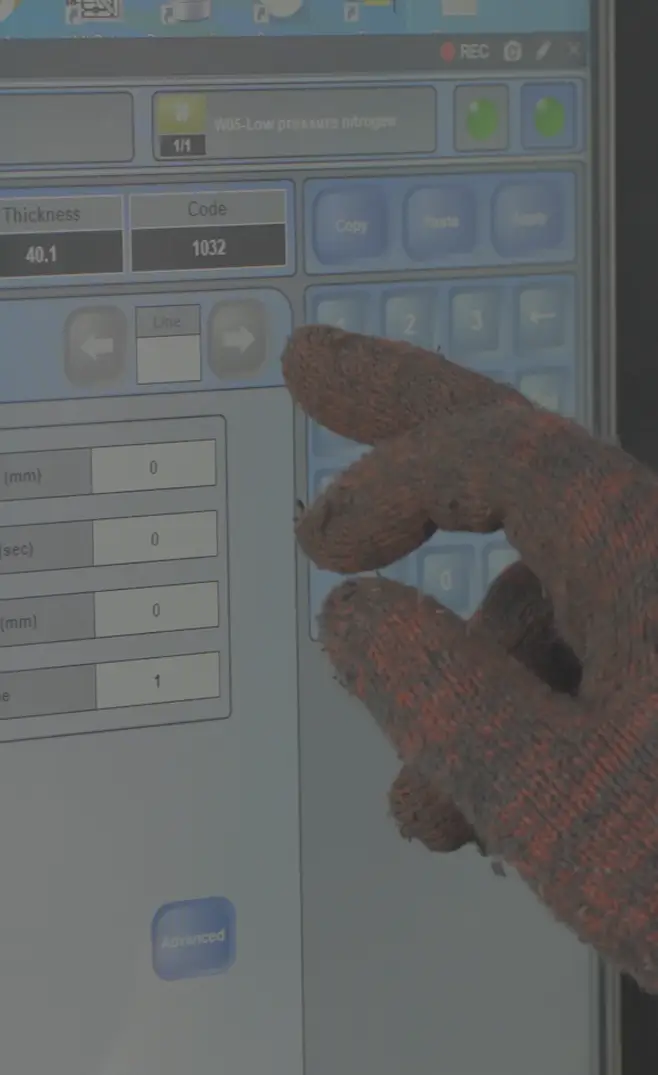

Production stays on cruise control from first tube to last. A semi-automatic loader and servo-guided roller supports align and feed each part, while follow-up flap unloading clears finished pieces for the next job, reducing forklift moves and operator fatigue. The fully enclosed cabin with triple safety interlock keeps crews protected, and Smart Manager CNC software stores proven cutting recipes so new profiles run right the first time. Add optional bevel cutting for weld-ready edges and you have a lights-out system that trims scrap, labor, and lead times in one move.

Specifications

Model:

12036

X Travel:

41' 8"

Y Travel:

29-1/8"

Z Travel:

18-7/8"

Positioning Accuracy:

0.0006"

Repositioning Accuracy:

.001"

Positioning Speed:

236 ft/min

Rotation Speed:

75 RPM

Rotation Accuracy:

8 arc-minutes

Bevel Cutting:

45°

Laser Power:

12000 W

Chucks:

3

Maximum Material Weight:

67.2 lbs/ft

Maximum Material Length:

40'

Operating System:

Smart Manager