Laser CNC Tube Cutting Machine

PeddiLS

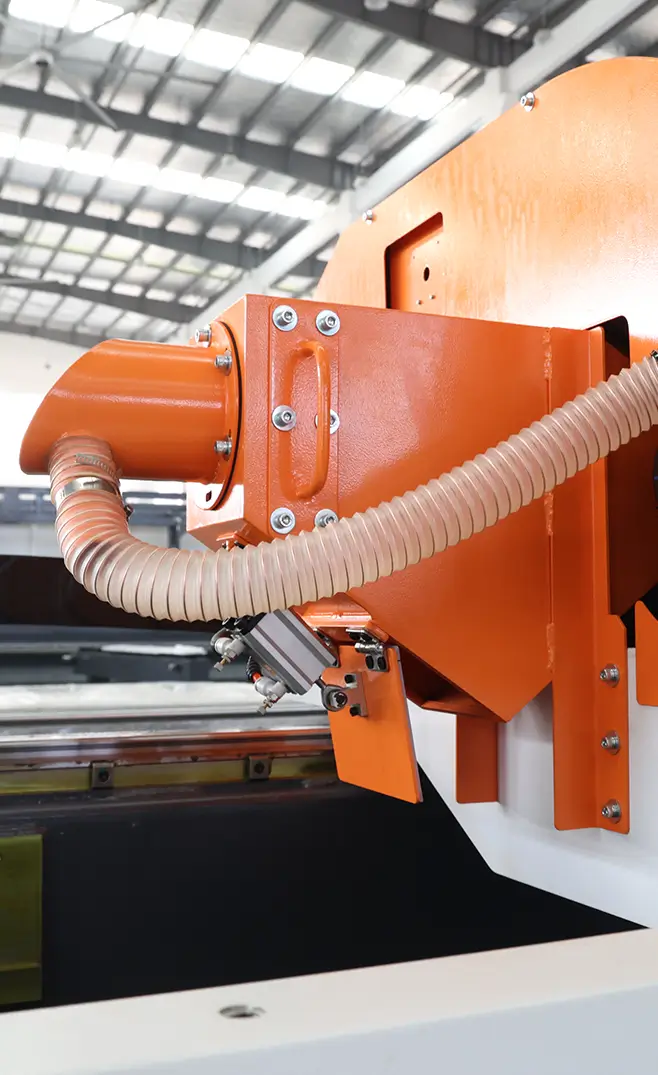

A high-speed tube and profile laser cutting system built for precision, automation and versatility

Overview

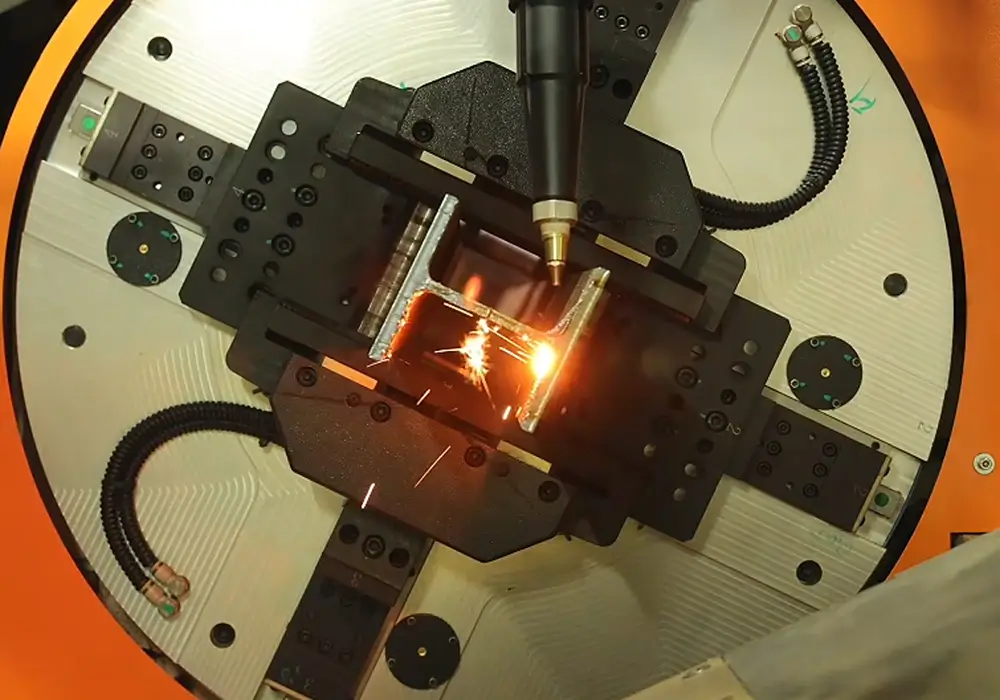

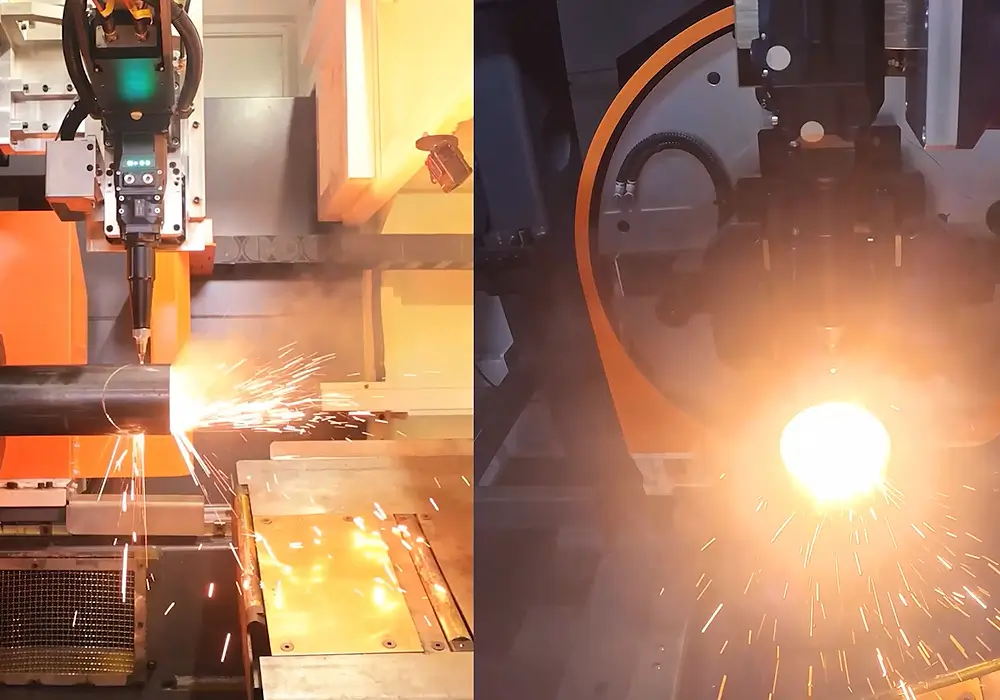

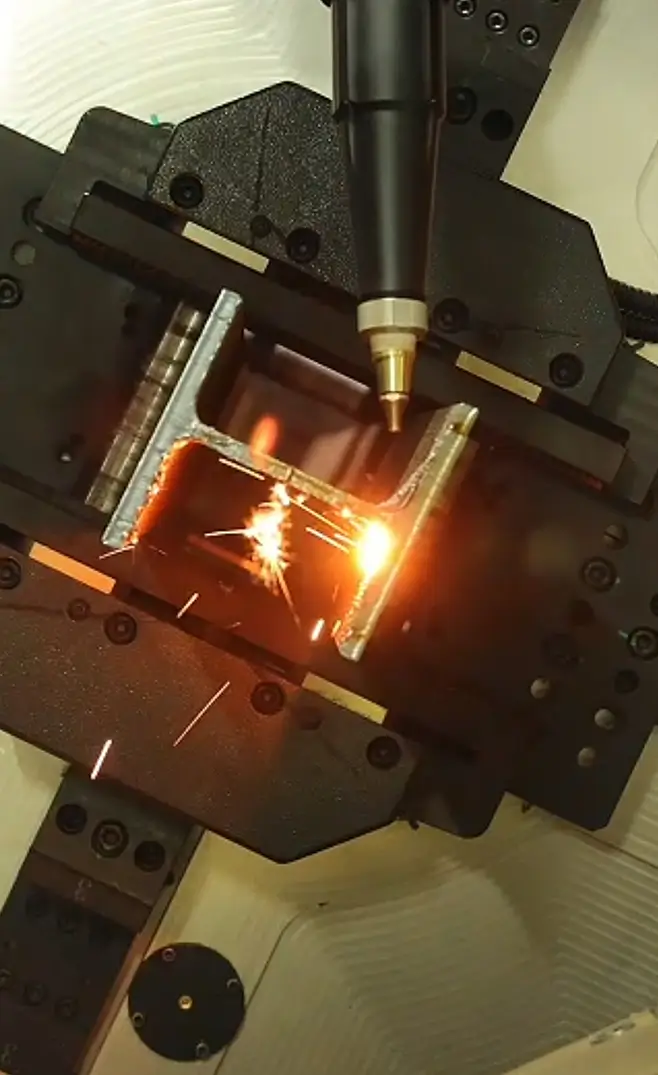

The PeddiLS laser cnc tube cutting machine is a dedicated profile laser system designed to deliver fast, accurate and repeatable cutting for round, square and structural shapes. Powered by a 6kW fiber laser and equipped with automated chucking, bevel capability and intelligent software, the PeddiLS streamlines tube processing while reducing setup time, labor and material waste. Ideal for structural steel, tube fabrication and high-mix production environments, the PeddiLS combines precision motion control with reliable automation to maximize throughput and cut quality.

Specifications

Base Model:

7528

X Travel:

1.51'

Y Travel:

24.61'

Z Travel:

.98'

Positioning Accuracy:

0.0006"

Repositioning Accuracy:

.00036"

Positioning Speed:

328 ft/min

Rotation Speed:

100 RPM

Rotation Accuracy:

.002"

Bevel Cutting:

45°

Laser Power:

6000 W

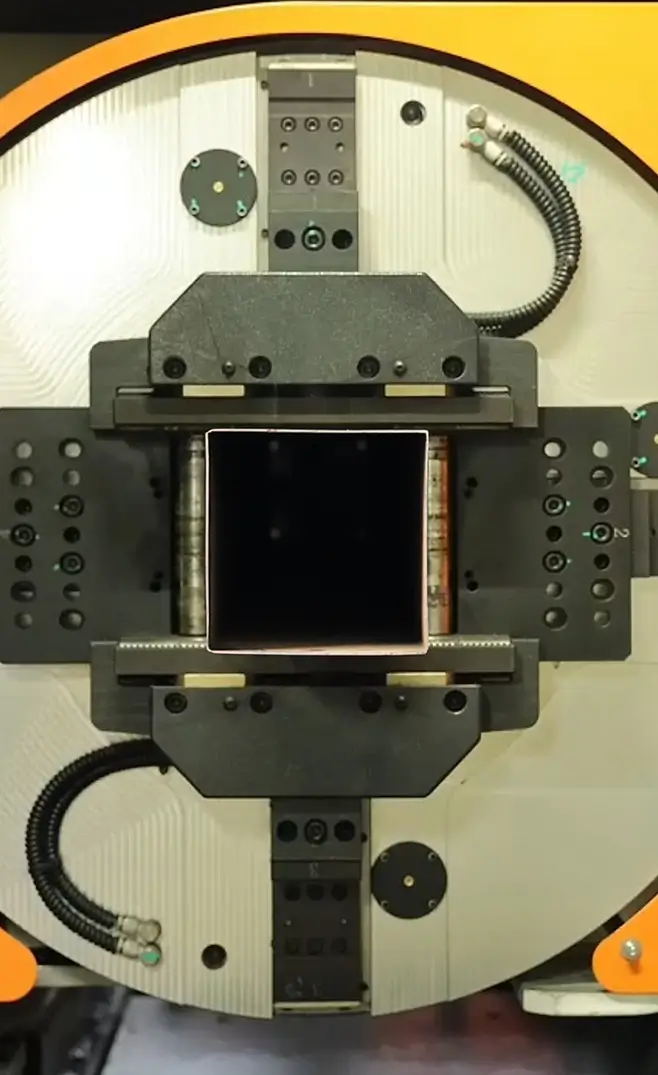

Chucks:

3

Maximum Material Weight:

33.6 lbs/ft

Maximum Material Length:

24.61'

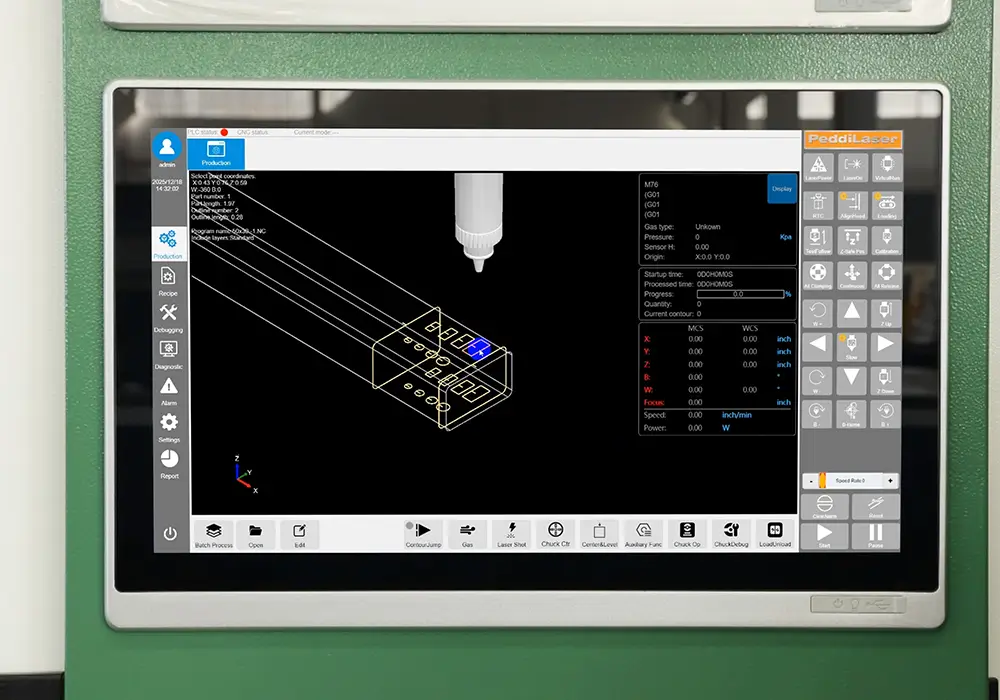

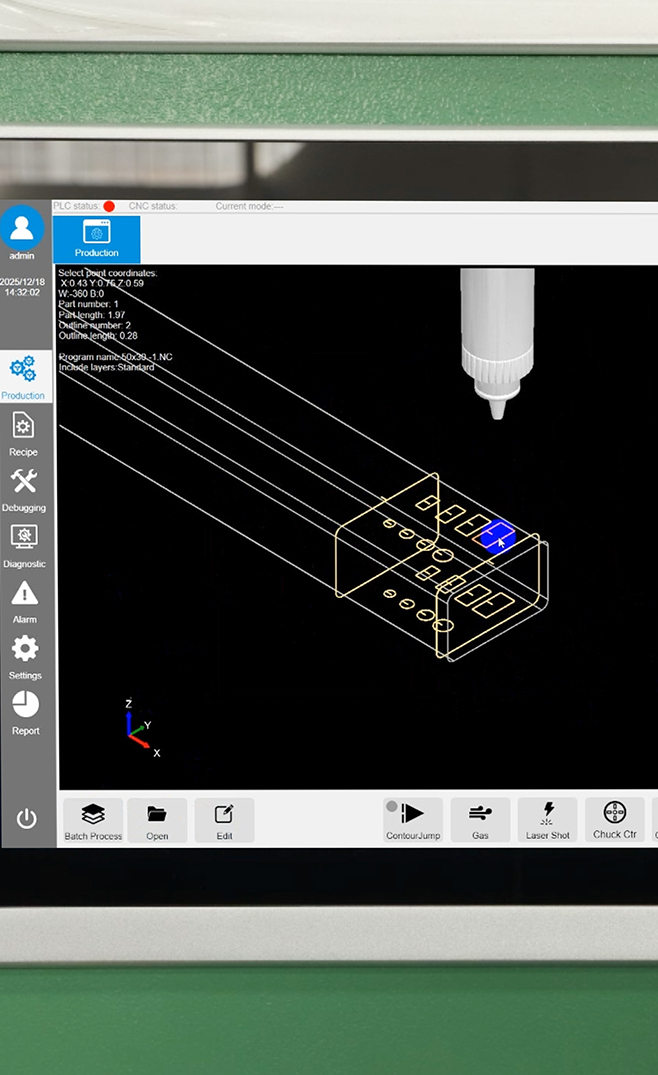

Operating System:

Beckhoff TwinCat 3

Nesting Software:

Lantek Flex3D Tubes Software